A Comprehensive Overview to Ceramic Coating and Its Function in Automobile Outlining Excellence

In the world of vehicle treatment and detailing, ceramic layer has actually arised as a game-changer. This innovative application, a fluid polymer, creates a durable, hydrophobic surface area that not only safeguards a lorry from ecological injury but also imparts a striking high-gloss coating. This article intends to dig into the scientific research behind ceramic finish, its numerous advantages, the application process, and succeeding upkeep tips - all contributing to vehicle detailing quality.

Understanding the Fundamentals of Ceramic Coating

While it might seem complicated in the beginning glance, the basics of ceramic finish are rather straightforward. Ceramic coating is a liquid polymer that is related to the external surfaces of automobiles. This finishing, which bonds chemically with the vehicle's manufacturing facility paint, produces a layer of defense. It is renowned for its capability to provide a shiny, high-grade surface that is not only visually attractive but additionally resistant to a range of possible damages, including scrapes and chips.

Its use is not restricted to cars and trucks, as it can also be related to other surface areas, such as plastic, glass, and metal. The application process calls for a certain degree of ability and precision and is typically carried out by professionals. This layer's sturdiness depends on numerous elements, consisting of the quality of the item and the conditions it is subjected to. In general, comprehending ceramic finish has to do with understanding its purpose, application, and benefits.

The Science Behind Ceramic Finishing and Exactly How It Functions

Looking into the scientific research behind ceramic coating, it becomes evident that its effectiveness is due to its special chemical homes. The finishing is made from a substance called silica dioxide, or SiO2, which creates a bond with the lorry's paint. This bond develops a semi-permanent, tough layer that shields the lorry's surface area.

The nanotechnology involved enables the ceramic particles to complete the min pores of the vehicle paint, making the coated surface area hydrophobic, or water repellent. This indicates that water, dust, and various other pollutants can not stick to the surface, instead they grain up and roll off.

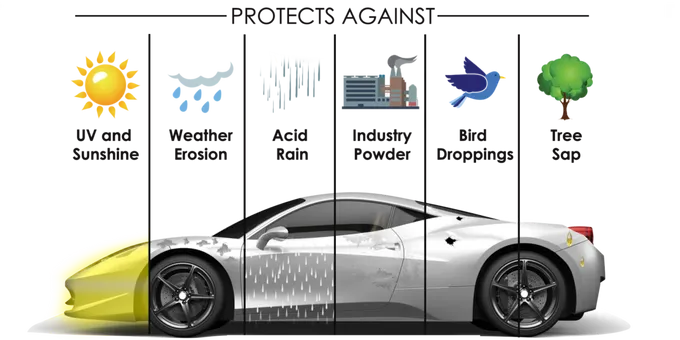

In addition, the chemical framework of ceramic layer offers it a high warm resistance. This makes it more resistant to the sunlight's UV rays and stops the automobile's paint from oxidizing and fading. Recognizing the science behind ceramic covering exposes just how this sophisticated technology provides an exceptional level of defense for cars.

Benefits of Applying Ceramic Coating to Your Lorry

Ceramic coating likewise enhances an automobile's look. It conveys a high-gloss finish that magnifies the cars and truck's color and general aesthetic appeals. This finishing is hydrophobic, implying it drives away water, making it harder for dirt and crud to adhere to the automobile's surface area. Because of this, cleaning becomes a less regular and easier task.

Finally, ceramic covering is a smart economic choice. It is a long-lasting investment that enhances an auto's resale value by maintaining its beautiful condition and sensational look. Unlike wax or sealant, ceramic finish does not call for constant reapplication, making it an economical solution.

Step-by-Step Process of Applying Ceramic Finish

Applying ceramic coating is a meticulous process that requires mindful precision and attention to i was reading this detail. The following action includes the use of a clay bar to get rid of any kind of recurring impurities, therefore preparing the surface for the application of the finish.

The real ceramic covering application is done using a little, soft applicator pad. The coating is used uniformly throughout the surface, panel by panel, in a cross-hatch pattern. This approach guarantees complete insurance coverage and uniformity. When used, the finish is allowed to heal. This procedure can use up to 24 hours.

This step-by-step process, while taxing, is vital to accomplishing the protective and aesthetic benefits of ceramic finish. It enhances the automobile's look, preserves its value, and guarantees its durability.

Maintaining Your Car Post Porcelain Coating: Tips and Tricks

Just how does one make certain the conservation of a ceramic coating's shine and durability? my website Post-application upkeep plays an essential duty. Making sure durability involves routine mild washing with pH-neutral soaps that will not break down the finishing. Avoiding harsh chemicals or unpleasant scrubbing tools is also vital.

It is suggested to dry out the car completely after washing to avoid water areas, which can possibly damage the covering - Detail'd Luxury Detailing & Coatings. Frequently applying a leading coat sealer can likewise boost the coating's longevity and heighten the glossy result

Nevertheless, the lorry ought to not be subjected to heavy rain or various other harsh problems quickly after finishing application. The coating needs time to cure properly, typically around 48 to 72 hours.

Verdict

To conclude, ceramic finishing supplies a cutting-edge way to improve a lorry's appearance while providing robust security versus ecological damage. It is a critical aspect of car describing excellence that improves resale worth and makes certain durability. By understanding the science, application process, and maintenance demands of ceramic finishing, vehicle lovers can accomplish a degree of describing that really stands the test of time.

Ceramic coating additionally boosts a vehicle's this page look.In final thought, ceramic finishing provides an innovative method to boost an automobile's appearance while providing durable protection against ecological damages. By comprehending the scientific research, application procedure, and upkeep demands of ceramic covering, vehicle enthusiasts can accomplish a level of describing that genuinely stands the test of time.

Rick Moranis Then & Now!

Rick Moranis Then & Now! Taran Noah Smith Then & Now!

Taran Noah Smith Then & Now! Ashley Johnson Then & Now!

Ashley Johnson Then & Now! Mason Reese Then & Now!

Mason Reese Then & Now! Lacey Chabert Then & Now!

Lacey Chabert Then & Now!